To work in close partnership with Customers, provide them with proven and innovative technologies and perform the best services to respect quality requirements and delivery dates, make research easier and provide safe working conditions for staff and environment are ABC Actini top priorities.

ABC Actini is also a team of experts specialized in engineering consulting services who mainly operates in bioprocesses and biocontained environments. Their knowledges in the latest regulations, evolutions and innovations of the sector are your keys for a perfect command of the processes, biological risks and safety rules that concern the very stringent field of the Bioprocessing.

Aware of the challenges represented by the implementation of critical process units, ABC Actini has established a global project management process aiming to ensure that all Customer’s expectations are fulfilled appropriately. It consists in assigning one dedicated project manager acting as a conductor to coordinate the experiences and expertise of our highly skilled technical teams so as to provide Customers with support and advice all along project phases from feasibility study through manufacturing, FAT, installation, SAT and validation to maintenance.

Design

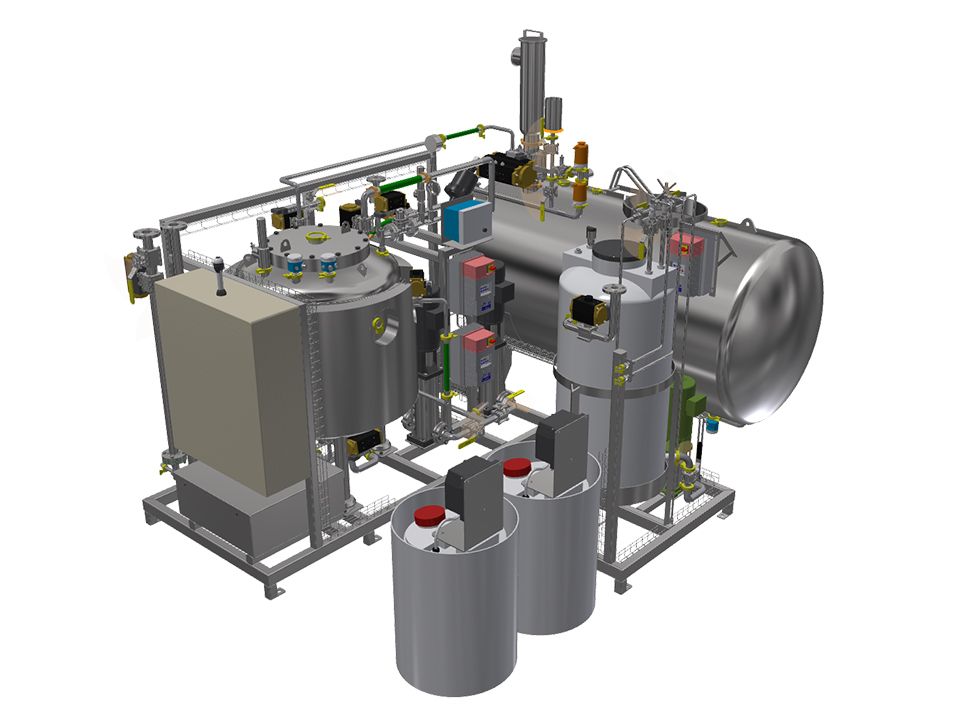

In close and constant collaboration with our Customers, our engineering teams develop solutions that enable to work on the basic design of their projects, define their specific needs and respond to their URS to offer the best economic and technical solution.

- Preliminary study: simplified functional analysis, equipment dimensions, preliminary layout, structure of automation for validation.

- Detailed study: manufacturing drawings, nomenclature, materials data sheet, and detailed functional analysis for validation.

- Design in accordance with the cGMP and CFR guidelines

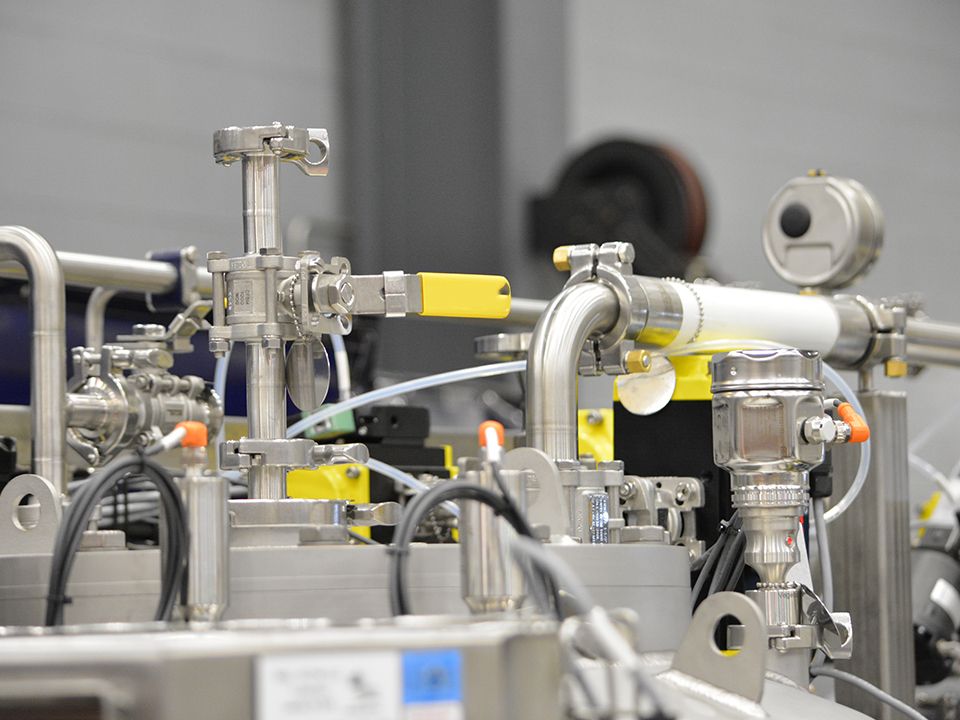

Manufacturing

Our systems are designed for long and reliable operational lifetimes. Our 7,000-sqm manufacturing site located in Bradford, PA, provides you with the warehousing capabilities required for pharmaceutical traceability in workshop spaces to accommodate the manufacturing of your systems.

Because a well-built system means a system which will easily and quickly pass all the tests and which will have a high level of future performance, ABC Actini teams pay particular attention to this step by carrying out a rigorous assembly.

Equipped with all the machines necessary for orbital welds, roughness finish levels… and above all experienced and multi-skilled technicians, our workshop allows you to follow the manufacturing of your systems in compliance with requirements and leads times.

Quality Assurance

ABC Actini has an unsurpassed quality assurance program and stringent quality standards. Our inspectors possess level II SNT-TC-1A visual and dye penetrant inspection certification. This allows them to inspect every product in production and perform meticulous final inspections. ABC Actini has an AWS-certified weld inspector, as well as an AWS-certified welding educator.

ABC Actini offers a variety of testing services available to our customers. Our products are designed to satisfy the requirements for the Pharmaceutical and Biotechnical Industries.

ABC Actini has an in-house AWS Certified Weld Inspector. Our welders adhere to the specifications & qualifications of ASME Section VIII Div.1 and ASME Section IX. We have the capability to perform factory acceptance testing with you, your customers and/or third party inspection services here at our facility. Our precision-engineered equipment sets the standard for quality and performance.

Certifications

- R Certificate – Allows us to repair and perform alterations to ASME Code stamped vessels.

- U & UM Certificates – Allows us to code stamp pressure vessels built to ASME Section VIII, Div 1.

- NB Certificate

- Marking Permission for CE stamping vessels

- 3-A For Filter Housings and Heat Exchangers

- UL 508A

- TSSA Process Piping

Codes & Standards: ASME Section VIII, Division 1 including UM, R, NB, U, BPE current addendum, CE stamped to European Pressure Directive for Categories I, II, III & IV, Pressure Equipment Directive, Bioprocessing Equipment Standards Committee, The National Board of Boiler and Pressure Vessel Inspectors, ASTM, B31.1 & B31.3, 3-A & GMP, CRN, Canadian Registration, TEMA, Singapore Ministry of Manpower (MOM), NBIC Repairs/Alterations…

ABC Actini is proud contributing members to ASME BPE that assist in bringing the very best in engineering and process component knowledge into the standard.

Factory Acceptance Tests (FAT)

Because ensuring that the equipment is compliant at our factory saves time during installation at Customer’s site and shortens time-to-market, Factory Acceptance Tests (FAT) are a milestone in the project life cycle.

They aim to control that the equipment operates in accordance with the URS and consist of tests and conformity checks including mechanical conformity, electrical conformity, automation tests, performance tests and documentary control before shipment.

Customers have the opportunity to witness the performance of these tests carried out by our skilled technicians in our factory.

On-site Setup & Commissioning

Some of our systems do not require any on-site setup or commissioning: just plug them in and they are operational.

For other systems, our qualified technicians, headed by the project manager dedicated to your project from the beginning, support you on your site to install, connect and commission your equipment in accordance with your URS.

Since the equipment has already been fully assembled in our factory and then meticulously and carefully disassembled and transported, it is much easier and faster to reassemble and install at your site.

This makes it possible to reduce on-site job and quickly move on to the testing and validation stages.

- Site setup

- Installation

- Commissioning

Site Acceptance Tests (SAT), Validation & Training

Our multi-skilled terams carry out all the testing and qualification protocols that will allow you to put your system into production very quickly and get a short time-to-market.

Just like FAT, the Site Acceptance Tests (SAT) which take place on the Customers’ site after full installation of the equipment are also an important step in the project life cycle because they secure that the system complies with your specifications. Since most of the testing has already been performed in our factory, our specialists are able to capitalize on FAT and deliver high quality and on-time SAT.

To ensure maximum system performance, our proficient specialists also provide your operators with appropriate and comprehensive training based on the “learning by doing” method.

- Preliminary tests and Site Acceptance Tests (SAT)

- Assistance to the IQ and OQ qualifications

- Training & ongoing service and support

Maintenance services

Even though our systems are designed and manufactured to last over time, to ensure that they are operating at peak performance and avoid hamstring downtimes, ABC Actini offers a range of solutions from spare parts delivery to maintenance services.

Our technical teams are at your disposal to:

- Maintain your equipment at its maximum efficiency through preventative maintenance services (periodic inspection, outline agreement).

- Intervene in the framework of curative or corrective maintenance with possibility of remote assistance through tools such as smart glasses

- Deliver spare parts

- Maximize the use and efficiency of your equipment

- Upgrade your existing facilities to improve their performances, perform regulatory compliance

- Upgrade the soft and automation programs

- Audit your facilities and help you maximize the use of your equipment