- Product features

- Product in action

- Ask a quote

Range

| MODELS | DAILY CAPACITIES | TECHNOLOGIES | ENERGIES |

|---|---|---|---|

| ULTIBATCH - single | 470 gallons | Batch | Steam |

| ULTIBATCH - double | 950 gallons | Batch | Steam |

Features

- Effluent BSL: 1-2-3

- Capacity: Up to 950 gallons per day

- Technology: Batch

- Utility: Steam

Decontamination

- Heat treatment with F050 depending on the required safety levels

- Standard set 275°F for 2 minutes or 257°F for 20 minutes (this latest set will impact the daily capacity)

- Specially adapted to treat effluent containing particles or viscuous products

- Available capacities: 470 gallons per day or 950 gallons per day (option)

- Guaranteed effluent decontamination with tangential steam injection which creates agitation within the kill tank, thus allowing faster and uniform heating

- Validation of the treatment efficiency by sensors and temperature control in several points including the coldest point.

- Ensured containment of contaminated effluent with enhanced safety devices

Design

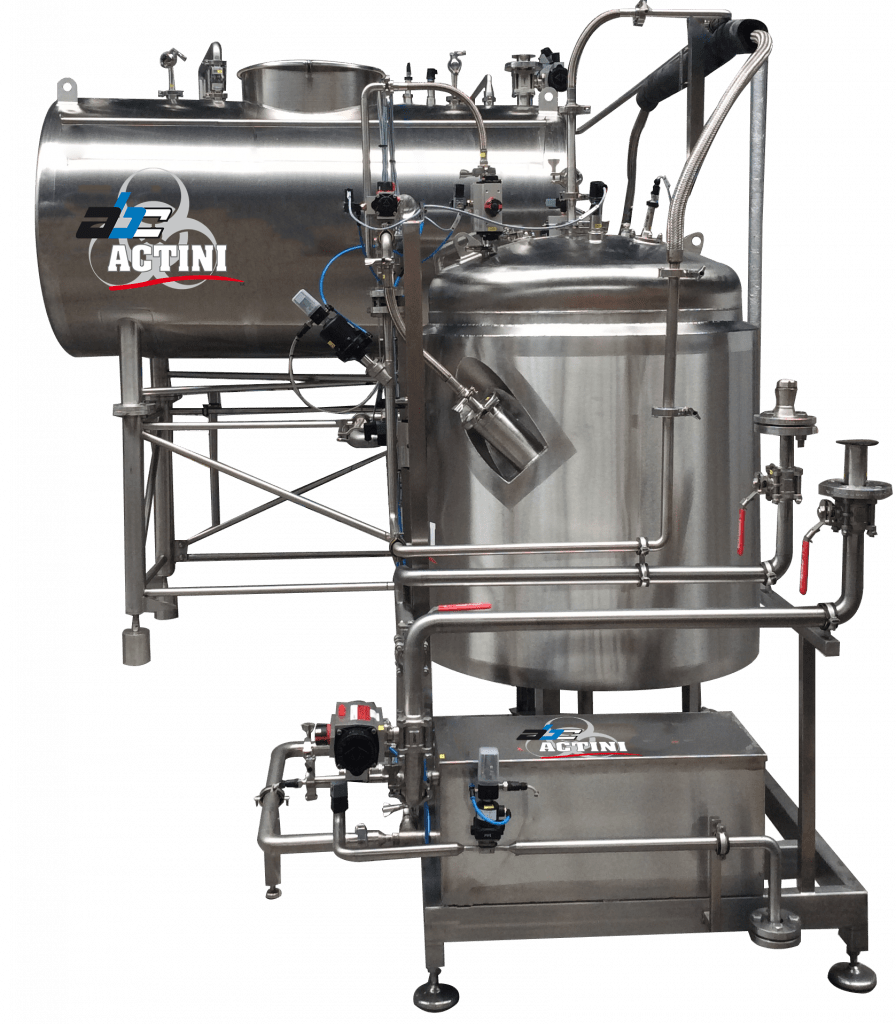

- Patented system

- Compact footprint: L: 83” – W: 36” – H: 80”

- Kill tank(s) with tangential steam injection

- Energy recovery section to consume less steam and less cold and enhance economy and ecology (included with the double treatment tank model only).

- Tubular cooling section

- Fully instrumented system and automatic operation through sensors and monitoring desk for automatic recording of cycles by PLC

- Steam operation – Chilled water required

Main options

- Double batch tank: by adding an extra kill tank and a coil recovery section, the daily capacity of the installation is doubled without increasing utility consumption, meaning that the consumption by cycle is almost divided by two.

- Steam generator

- Condensate management

- Pumping skid: necessary if the height of the room is not high enough for the storage to be in upper position than the Ultibatch to fill it by gravity

- Cleaning in place: mounted on wheels, the mobile CIP enables complete cleaning of the system and can be stored elsewhere during the normal operation and moved close to the equipment during the cleaning cycles

- Other options available

Tangential steam injection

Pictures of the ULTIBATCH in action

Contact our sales department

To receive more information about our products in the USA and Canada, please contact us.