- Product features

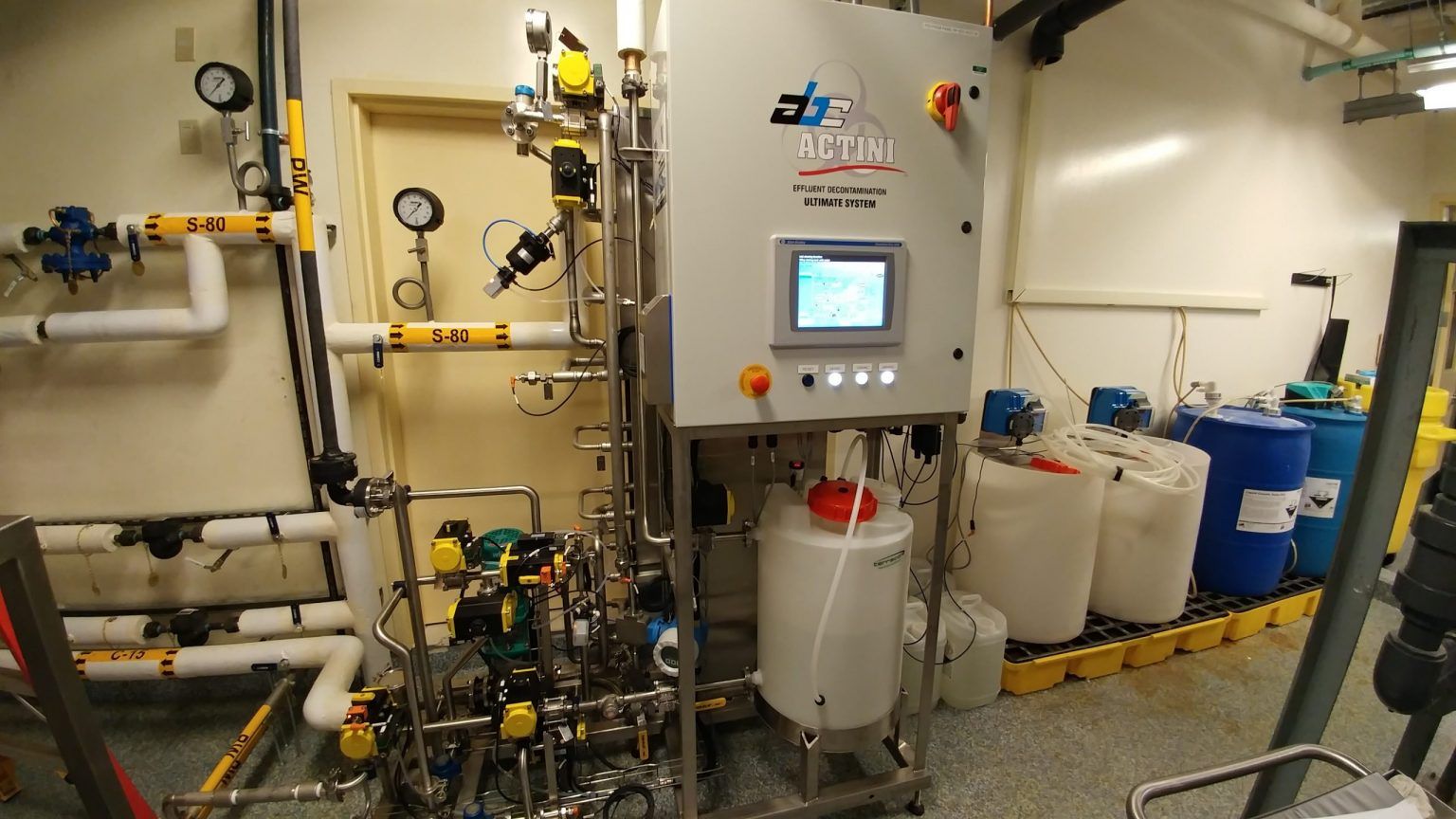

- Product in action

- Ask a quote

Features

- Effluent BSL: 1-2-3

- Capacity: Up to 4,200 gallons per day

- Technology: Continuous flow

- Utility: Steam

Decontamination

- Heat treatment with F0 > 25 depending on the required safety levels

- Standard set: 176°F to 275°F – 1 minute

- Effluent decontamination capacity: from 1,300 to 4,200 gallons per day

- Recommended daily operation: up to 16 hours per day

- Guaranteed decontamination through eddy diffusion (turbulence)

- Validation of the treatment temperature and efficiency by sensors

- Ensured containment of contaminated effluent with strict safety devices such as emergency shutdown valve in case of dangerous event detection

Design

- Tubular design allowing continuous treatment of large volumes of biowaste effluent

- Ultra-compact design: W: 32” – L: 56” – H: 87”

- All welded heat exchangers to avoid any risk of leakage and cross-contamination

- Energy recovery section to pre-heat and pre-cool biowaste effluent (savings of 80% of heat energy used)

- Compliance with American standards

- Starting tank and CIP (Cleaning in Place) preparation

- CIP tanks for CIP solutions storage (Cleaning in Place)

- Pumping system secured by a filter

- Treatment section with energy recovery system

- Fully instrumented system (temperature sensor, flowmeter, pressure and level transmitters, valves) for total automatic operation of the unit: it starts based on a level sensor, stops and washes without any intervention

Main options

- Cleaning in Place skid to clean the system

- Manual Cleaning in Place

- Effluent holding tank to collect and store effluent before treatment if not supplied by the Customer

- Cooling by tubular exchanger

- Neutralization system

Pictures of the ULTIMATE in action

Contact our sales department

To receive more information about our products in the USA and Canada, please contact us.