- Product features

- Product in action

- Ask a quote

Range

| MODELS | DAILY CAPACITIES | TECHNOLOGIES | ENERGIES |

|---|---|---|---|

| ULT-3000 | 2,600 to 12,700 gallons | Continuous flow | Steam |

| ULT-3000 + EXT3000 (x1) | 7,900 to 25,400 gallons | Continuous flow | Steam |

| ULT-3000 + EXT3000 (x2) | 13,200 to 38,000 gallons | Continuous flow | Steam |

| ULT-3000 + EXT3000 (x3) | 37,000 to 50,700 gallons | Continuous flow | Steam |

Features

- Effluent BSL: 1-2-3

- Capacity: Up to 50,700 gallons per day

- Technology: Continuous flow

- Utility: Steam

Decontamination

- Heat treatment with F0 > 25 depending on the required safety levels

- Standard set: 176°F to 275°F – 1 minute

- Effluent decontamination capacities: from 2,600 to 50,700 gallons of effluent per day

- Capacity upgrades easy to integrate by connecting 790-gal/hour modules

- Recommended daily operation: up to 16 hours per day

- Guaranteed steam decontamination with validation of the treatment temperature and efficiency by sensors

- Ensured containment of contaminated effluent with strict safety devices such as emergency shutdown valve which actuates in case of dangerous event detection

- In case of failure in the decontamination cycle, a safe return of the effluent to the storage tank is made automatically.

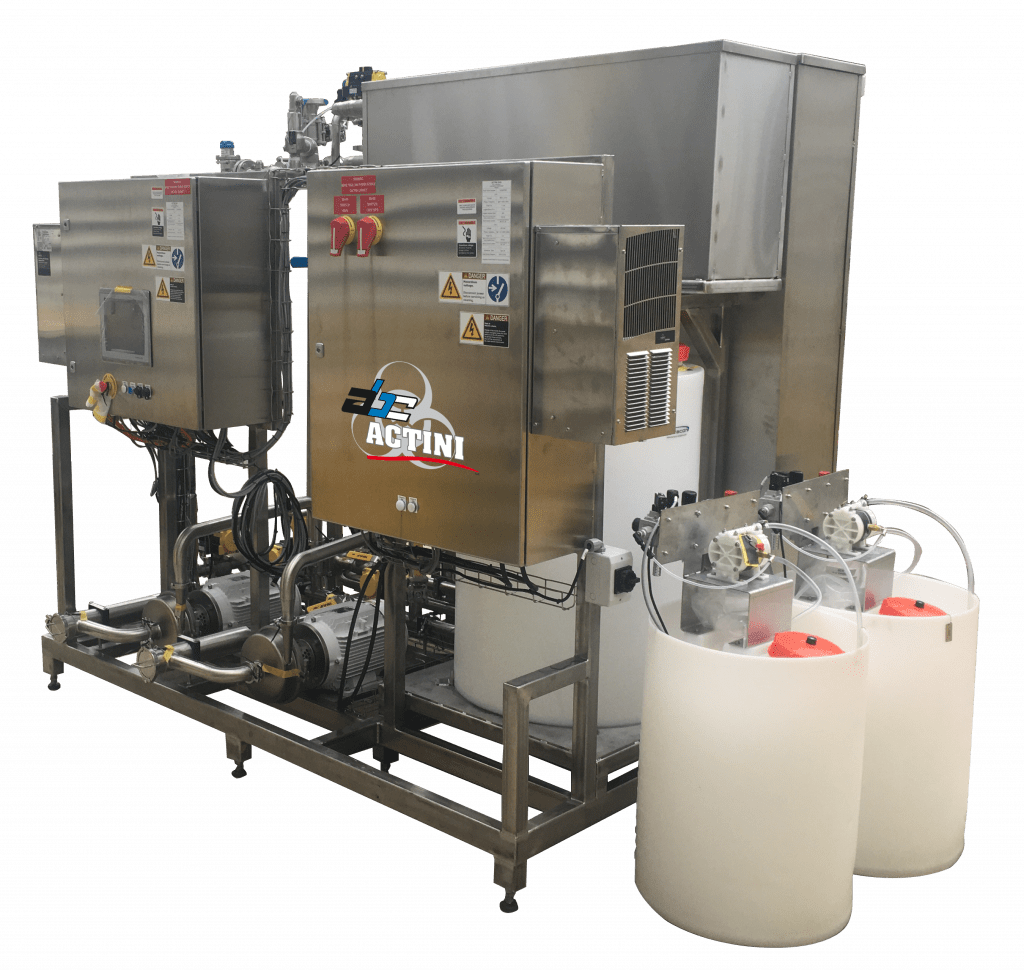

Design

- Tubular design allowing continuous treatment of large volumes of biowaste effluent

- Ultra-compact design of the add-ons:

- Main skid: W: 27” – L: 98” – H: 93”

- Each add-on: W: 37” – L: 100” – H: 93”

- All welded heat exchangers to avoid any risk of leakage and cross-contamination

- Energy recovery section (savings of 80% of thermal energy used)

- Possibility to double the pumping system for redundancy

- Automatic operation controlled from the main skid: no automation study required when connecting add-ons

- For maintenance operations, performance of a full automatic direct steam sanitization to ensure the Operator safety

- Remore access

- Compliance with American standards

Equipment components

- Starting tank and CIP (Cleaning in Place) preparation

- CIP tanks for CIP solutions storage (Cleaning in Place)

- Pumping system secured by a filter

- Treatment section with energy recovery system

- Fully instrumented system (temperature sensor, flowmeter, pressure and level transmitters, valves) for total automatic operation of the unit: it starts based on a level sensor, stops and washes without any intervention

Main options

- Effluent holding tank to collect and store effluent before treatment if not supplied by the Customer

- Extension of holding time from 60 up to 120 seconds

- Cooling by tubular exchanger

- Cleaning in Place skid to clean the system

- CIP tanks

- Neutralization system

Pictures of the ULTIMATE PLUS in action

Contact our sales department

To receive more information about our products in the USA and Canada, please contact us.